Lithium-Sulfur Batteries: A Game-Changer for Electric Vehicles

As technology continues to evolve, the battery demands of a modern EV/HEV/PHEV require increased electrical potential available for all the systems that are being implemented to increase operational features. From high voltage climate control to increased integration with the Internet of things, the demand on the power a vehicle has is ever increasing. This increase of power demands requires new thoughts and investigations of materials that potentially can be utilized for battery cell chemistries. Looking for materials that are easily accessible, reasonably priced and abundant will continue to drive the battery market for the foreseeable future. Lithium-Sulfur battery technology is just one of those avenues.

What are Lithium-Sulfur Batteries?

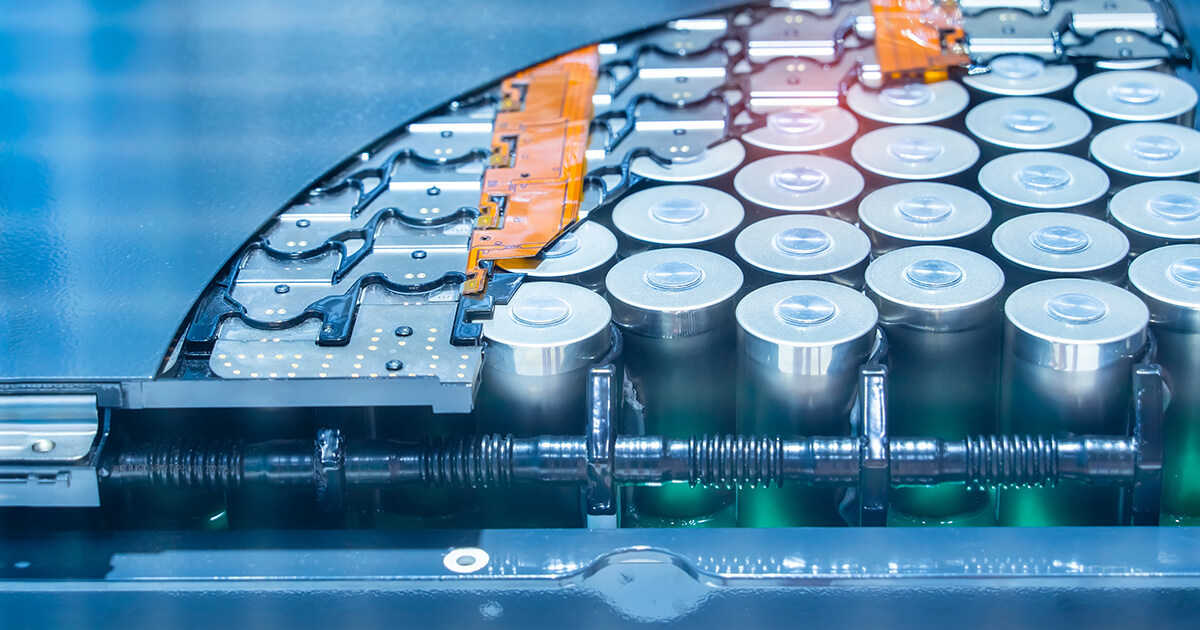

Most current Lithium-ion cell structures utilize Lithium metal as an anode and Carbon as a cathode. This is a robust combination that helps to maintain costs as carbon is plentiful throughout the world and is stable as opposed to other materials. Lithium-sulfur (Li-S) batteries are a type of rechargeable battery that use sulfur as the cathode material and lithium as the anode. Unlike lithium-ion batteries, which rely on lithium compounds and other metals such as cobalt or nickel, Li-S batteries leverage sulfur, an abundant and inexpensive material. The combination of metallic lithium and sulfur (graphene) can potentially store 2 to 5 times more energy than traditional lithium-ion batteries, making them a highly attractive option for applications that require a high energy dense cell for high load devices. When the ions leave the anode and interact with the Sulfur in the cathode, Lithium Polysulfides (LiPs) form (Stojkovski, 2024). As the breakdown of these polysulfides continues energy is released in the process.

One of the main issues with this battery type that is causing degradation is the dissolution of the polysulfide in the electrolyte (Zhao et al., 2020). This dissolution causes the life cycle of this cell to diminish and is not a viable option for EV applications. Through the new hybrid matrix structure in the electrolyte, the polysulfide ions bond to that structure and help to stop the dissolution of the ion thus reducing the degradation of the cathode material and the life of the cell (Stojkovski, 2024).

Why Choose Lithium-Sulfur Batteries?

Sulfurized polyacrylonitrile (SPAN) has emerged as a one of the high energy dense Li-S battery chemistries (Phan et al., 2024). Through this recent study the ability of the cell to have a relatively small electrode weight has increased the energy density of the material. This increased energy density has helped to make the ability of this cell increase the potential power capacity by 12-20% (Phan et al., 2024). As the density increases, the size of the pack needed to provide power to the vehicle will shrink. This shrinkage will allow better integration within the vehicle itself or the increase in battery pack size to meet the mileage requirements of the consumer. This breakthrough also provides the cell with the robustness to last within an automotive environment and sustain operational conditions for an extended period.

The reduction of rare earth metals in the production of the battery cell with the use of Li-S types of technology reduces the cost of cell production as well as outsourcing of materials. With this reduction of cost, the cell is more abundant and cheaper than other chemistries. As the rare earth metals are reduced, the weight of the cells will continue to decrease. The decreasing weight will increase the efficiency of the vehicle thus helping to increase the range. As this technology progresses, the use of Li-S in solid state applications increases its viability by minimizing the potential for degradation from ion movement through the electrolyte. The combination of this technology with solid state technology provides for increased efficiency due to the elimination of LiPs formation and shuttling (Ding et al., 2020). This decrease in stressors on the battery cell provides for a more stable power capacity, life cycles and overall, a more stable battery chemistry.

Conclusion

The battery chemistry technology is expanding at a rapid pace throughout the OEM landscape. Looking for the next possible industry changing technology pushes the automotive battery engineer to look in uncommon places for something that will meet the needs of the vehicle along with having easily accessible materials for production. The Li-S chemistry is something that helps to lower the amount of rare earth metals present in the battery cells which helps to lessen the dependence on the few countries that have access to this material, helps to minimize the mining of these materials and increases the self-reliance of the producer by bring the distance from materials to finished product to a more reasonable area. The ability of the Li-S chemistry to meet the automotive output and charging requirements moves it into a contender for automotive applications. Stellantis is currently testing the applications of Li-S chemistry cells within their electric vehicle platforms (Lewis, 2024). Lyten is providing the cells to Stellantis, they are utilizing a 3D graphene structure within the cathode to help increase stability of the cell and helps to mitigate the polysulfide shuttle as well as support higher charge/discharge rates (Lyten, 2024). This path opens the possibility of mass production of battery cells without rare earth materials which will drive down costs and increase production possibilities.

The MAST series of CDX provides the instructor pointed material to exceed the requirements of any ASE training currently on the market. Utilizing the Read-See-Do model throughout the series, the student has various learning modalities present throughout the products which allows them to pick the way they learn the best. From developing simulations on cutting edge topics to providing a depth of automotive technical background, CDX has a commitment to making sure instructors and students have the relevant training material to further hone their skill sets within the mechanical, electrical and software driven repair industry. CDX Learning Systems offers a growing library of automotive content that brings highly technical content to the classroom to keep you and your students up to date on what is currently happening within the Mobility Industry.

Check out our Light Duty Hybrid and Electric Vehicles, along with our complete catalog Here.

References

Ding, B., Wang, J., Fan, Z., Chen, S., Lin, Q., Lu, X., Dou, H., Kumar Nanjundan, A., Yushin, G., Zhang, X., & Yamauchi, Y. (2020). Solid-state lithium–sulfur batteries: Advances, challenges and perspectives. Materials Today, 40, 114–131. https://doi.org/https://doi.org/10.1016/j.mattod.2020.05.020

Lewis, M. (2024, May 10). Stellantis is about to test the first-ever production-line lithium-sulfur batteries. Electrek. https://electrek.co/2024/05/10/stellantis-is-about-to-test-the-first-ever-production-line-lithium-sulfur-batteries/

Lyten. (2024, November 10). Lithium-Sulfur Batteries. https://lyten.com/products/lithium-sulfur-batteries/

Phan, A. L., Nan, B., Le, P. M. L., Miao, Q., Wu, Z., Le, K., Chen, F., Engelhard, M., Dan Nguyen, T., Han, K. S., Heo, J., Zhang, W., Baek, M., Xu, J., Zhang, X., Liu, P., Ma, L., & Wang, C. (2024). Lightweight Electrolyte Design for Li/Sulfurized Polyacrylonitrile (SPAN) Batteries. Advanced Materials, 36(35). https://doi.org/10.1002/adma.202406594

Stojkovski, B. (2024, October 26). Lithium-sulfur EV batteries last longer with higher energy using SMU method. Interesting Engineering. https://interestingengineering.com/energy/smu-long-lasting-renewable-ev-batteries

Zhao, M., Li, B. Q., Zhang, X. Q., Huang, J. Q., & Zhang, Q. (2020). A Perspective toward Practical Lithium-Sulfur Batteries. ACS Central Science, 6(7), 1095–1104. https://doi.org/10.1021/acscentsci.0c00449

About the Author

Nicholas Goodnight, PhD is an ASE Master Certified Automotive and Truck Technician and an Instructor at Ivy Tech Community College. With nearly 20 years of industry experience, he brings his passion and expertise to teaching college students the workplace skills they need on the job. For the last several years, Dr. Goodnight has taught in his local community of Fort Wayne and enjoys helping others succeed in their desire to become automotive technicians.